Career path: How I became a meat grader

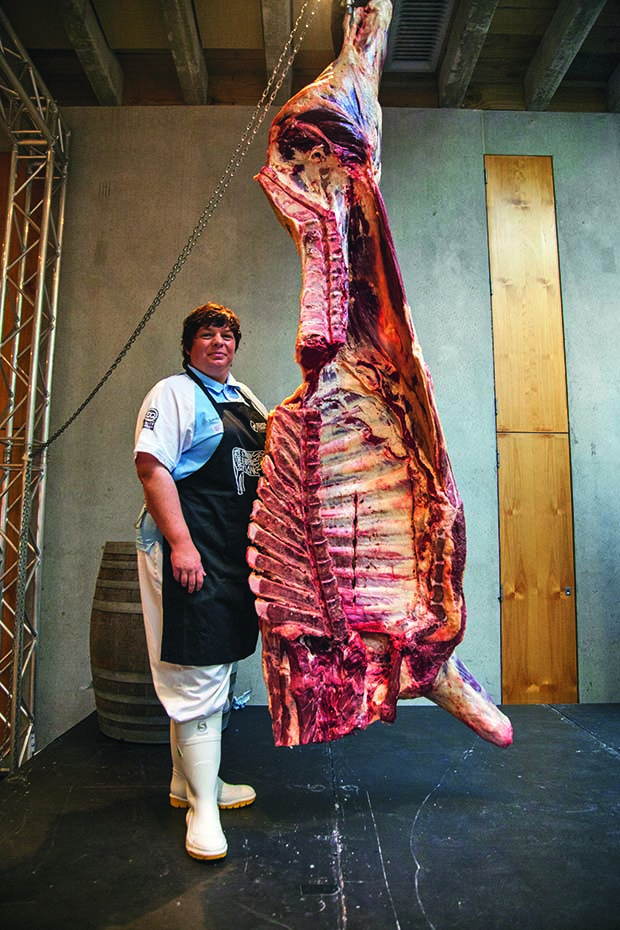

Sarah Duncan appreciates a good steak — her career is dedicated to assuring that the meat on Kiwi forks is of the highest possible standard.

Words: Cheree Morrison

This article was first published in the May/June 2016 issue of NZ Life & Leisure.

1990: Taradale High School

A Hawke’s Bay girl born and bred; was too busy focusing on competing swimming at a national level to think about what came next.

1995: Massey University

Graduated with a Bachelor of Science majoring in microbiology and biological science. “I went to university in the hopes of finding that clicked. I thought science would be an easy option, but I discovered I loved it and it came naturally. Massey Uni was fantastic; I had excellent tutors who spurred me on to continue in the industry.”

1996-97: Wairoa to London

Worked as a microbiology technician in a Wairoa Lab but she found it wasn’t overly fulfilling. Jumped on a plane to London via North America, and worked in a bar for eight weeks. Remembered that a client she used to fax weekly reports to from her Wairoa lab worked in London. Figured “why not?” and gave him a call. It turned out he was the head meat technologist for Sainsbury’s in the UK, and happily provided three contacts. Met Sheila Gray, group technical manager for Grampian Country Food Group, who was starting a six month quality-assurance (QA) graduate programme with emphasis on a plough-to-plate philosophy. QA is different to quality control (QC) – QC checks everything coming off the line, whereas QA creates and monitors the programmes and processes that QC uses.

1998: Quality manager in chicken processing factory, Grampian Country Foods

Flew the coop to Aberdeen — she considered the job with lamb in Wales but decided to add another protein to her wing choosing chickens. Met husband Johnny during her first week on the job. Moved around northeast Scotland and Edinburgh working a variety of positions with the Grampian Country Food Group.

2004: Moved to Bangkok

“Johnny was offered a great opportunity in Thailand so off we went with Maxwell, our year-old son. I wasn’t eligble for a working visa so I spent two years making the most of everything Bangkok has to offer.” Joined the Australian and New Zealand Women’s Group, which fund-raised a lot of money to help Thai children. Returned to Edinburgh in 2006 while 35 weeks’ pregnant and spent the next few years enjoying her favourite job — mum.

2009: Quality assurance for Silver Fern Farms

“My mum was ready for me (and the grandkids) to come home, so sent a job application for a position with an old colleague. I began in quality assurance for Silver Fern Farms in Takapau, then moved to a technical manager position in Hastings, overseeing a team of people.” Was involved in a project developing Silver Fern Farms’ eating-quality grading system, created in conjunction with Otago University and Texas Tech. “It’s a science-based system that guarantees the quality of our beef product. Only four of every 100 animals make the grade, and that’s the product selected for retail packs.

2014-16: Technical manager for improved quality systems, Silver Fern Farms

“I’m excited by the way we can use the latest technology to improve our existing quality systems. Food production has been standard for a long time. Currently the team is working on a revolutionary upgrade of our existing quality system, which will use the latest technology to capture and report on data. It’s never been done.”

2011-16: Joint owner of No.5 Cafe and Larder

“After both working in the food industry for over a decade, husband Johnny and I needed a change. We wanted to explore the retail world and No.5 in Hastings, with it’s cafe conference centre and activities was a good fit. We thought we were busy before; now we are proper busy. We’ve been lucky and have had fantastic support from family, friends and staff. Johnny is there full time. I help out after work at Silver Fern Farms, and we’ve both found our QA skills are transferable. QA is about setting an expectation of what a customer wants and meeting it. They should always know exactly what they are getting from you.”

LIFE LESSONS

A great team is critical.I’ve been lucky that my family have always supported me in making the most of any opportunities but I also couldn’t have done it all without a fantastic team of colleagues beside me. Communicating well with that team is also vital — never underestimate people skills. Sometimes a policy can be well written, but needs to be put across to people in their language. Learn to speak in their language and tone.

Timing is key. If something isn’t working; wait until the timing is right. Forcing something to happen causes angst; take a deep breath and approach it again at another time. Sometimes people need time to adjust to change as well — some people accept change on the spot, others need time to let it digest.

Slow down the pace. It took us a while to adjust back to the New Zealand pace; for the first few months we were early to everything — we once showed up at birthday party 20 minutes before the building even opened. Living in Bangkok, Johnny sat in the traffic for 80 minutes every evening. In Hastings, there have been three occasions when we haven’t made it through the traffic lights in a single phase. We’ve kept count.

Love this story? Subscribe now!

This article first appeared in NZ Life & Leisure Magazine.

This article first appeared in NZ Life & Leisure Magazine.